Joint venture partners Kioxia and SanDisk are previewing faster 218-layer 3D NAND with accelerated interface speed and better power efficiency, plus a forthcoming 332-layer technology.

Their current Gen 8 BiCS technology has 218 layers and was introduced last year. SK hynix broke the 300-layer barrier in November 2024 when it launched a 321-layer product, stringing three 100-plus-layer stacks together. Kioxia and SanDisk’s BiCS 9 generation will use new NAND interface technology in its CMOS logic layer, coupled to the existing 218-layer NAND cell package, for higher performance and lower power consumption. They are also revealing a future BiCS 10, with the new logic layer tech bonded to a 332-layer NAND unit. This 300-plus-layer tech was first mentioned at SanDisk’s investor day last week.

Kioxia Europe VP and CTO Axel Stoermann said: “Next to the demand for increased power efficiency in datacenters, data generation is set to vastly increase, driven by new AI technology-driven applications, with sophisticated operations such as inference at the edge and the application of transfer learning techniques further compounding storage requirements.”

SanDisk and Kioxia have increased the NAND chip interface speed by 33 percent in BiCS 9 by using the Toggle DDR6.0 interface plus the SCA (Separate Command Address) protocol. This has separate control and data paths that operate in parallel. Their tech also features PI-LTT (Power Isolated Low-Tapped Termination) technology in which “power sources for existing 1.2 V and additional lower voltage are utilized for the NAND interface power source. This reduces power consumption during data input/output” by 10 percent for input and 34 percent for output. Because of this, the BiCS 9 NAND chip interface speed should be 4.8 Gbps.

The combination of the 332-layer count and better planar cell layout increases bit density by 59 percent in the forthcoming BiCS 10 technology, compared to BiCS 8 and 9, the pair say.

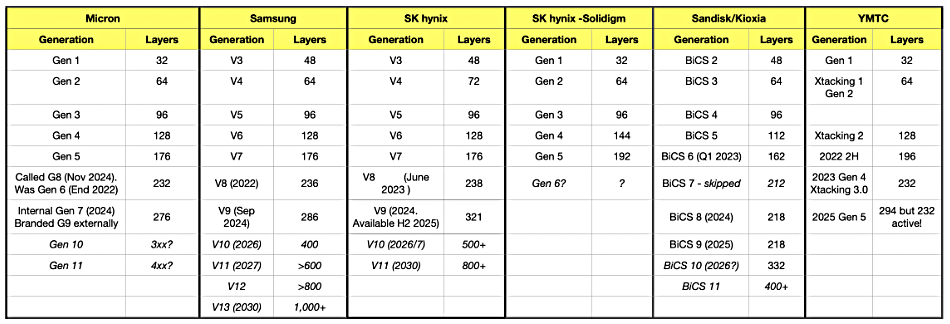

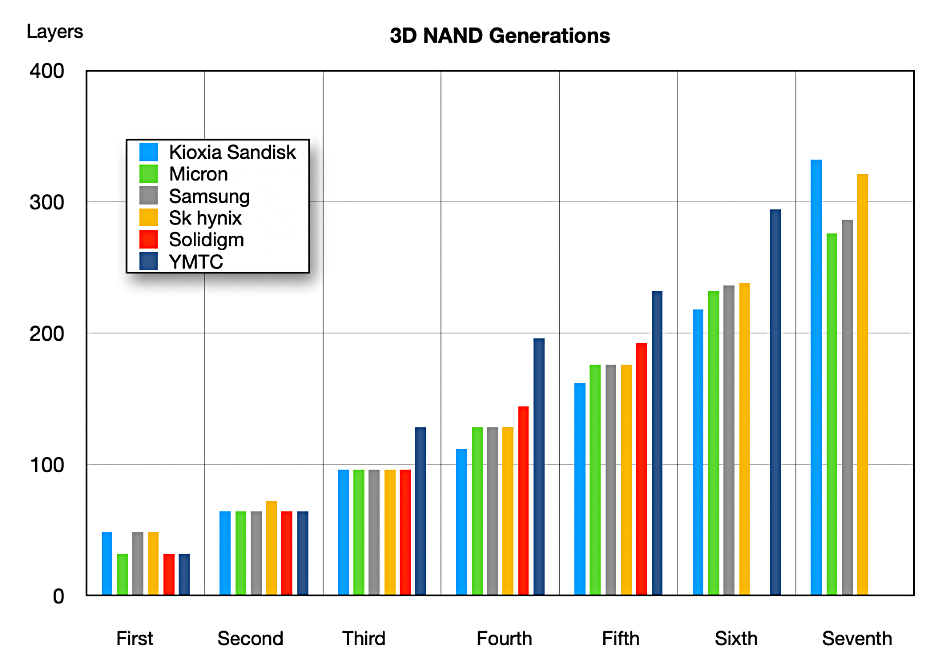

A table shows the current layer counts for the six suppliers and their fabs:

Although Solidigm is owned by SK hynix, it has a separate fab infrastructure and technology. If we look at a chart of these supplier numbers, we can see seven generations of this technology, although the suppliers’ internal generation branding is different.

All suppliers except Solidigm broke the 200-plus-layer level in a sixth generation of their products in the 2022-2023 period. Now Kioxia-SanDisk are introducing a second 218-layer class product, one with the faster interface detailed above.

We also see that China’s YMTC (dark blue column) has had the highest layer count in each generation in our chart, since the third. It’s possible, if not probable, that it will head towards the 350 or greater level in its next technology leap to do the same again in our seventh generation category.

It’s also apparent that Solidigm, although producing 128 TB-class QLC SSDs, the highest capacity available, is using fifth-generation 192-layer product. We expect Solidigm to announce a fresh generation of 3D NAND that moves closer to or even into the 300-plus-layer area. Solidigm’s owner, SK hynix, is already at the 321-layer point.

Bootnote

Toggle mode NAND uses a double data rate interface for faster data transfers, and a multiplexer (MUX) manages the data lanes.