Dell server sales boom but storage lags

Dell reported $23.9 billion in revenue for the quarter ended January 31, 2025, up 7 percent year-over-year, with a 27…

Nutanix sees revenue surge as VMware customers flee Broadcom acquisition

Nutanix recorded a double-digit revenue increase, at least partly ascribed to sales to disgruntled Broadcom VMware customers who jumped ship…

Scale Computing claims sales growth amid demand for VMware alternative

Edge hyperconverged infrastructure player Scale Computing is claiming strong annual growth for its solutions across the market. The company, which…

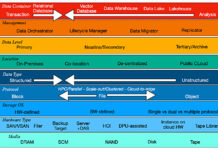

Storage stack layers and players going into 2025

Analysis: Right now, the two dominant storage demand and development drivers are cyber-resilience and security on the one hand, and AI…

Virtuozzo leadership revamp targets VMware switchers

Virtuozzo has had a executive restructuring with founder Serg Bell returning to the CEO role, along with other senior exec…

Storage news roundup – December 13 2024

Aerospike unveiled the latest version of Aerospike Vector Search, featuring powerful new indexing and storage innovations that deliver real-time accuracy, scalability,…

Solidigm SSDs supercharge VergeIO performance for VMware switchers

VergeIO’s updated VergeOS software delivered more than 1 million IOPS from a six-node cluster with Solidigm SSDs as the company…

Nutanix beats forecast with 16% revenue growth for Q1 FY25

Nutanix revenues grew 16 percent year-on-year to $591 million as it comfortably beat its $575 million high point outlook. It…

Scale Computing talks up edge site and VMware replacement business

Scale Computing’s revenue and customer count growth has accelerated as customers flee VMware and more edge computing sites adopt hyperconverged…

Microsoft and AWS lead Gartner report on distributed HCI market

The top two public clouds – Amazon's and Microsoft's – lead the distributed HCI market in Gartner’s Magic Quadrant (MQ)…

Dell’s server revenue bumper jumper

A massive rise in server sales led Dell’s second fiscal 2025 quarter revenues to a 9 percent year-on-year rise to…

Nutanix raises revenue notwithstanding large deal pushout

Nutanix beat the street with its latest results driven by a strong contract renewals performance and increased sales in its…

VergeIO adopts HashiCorp tool to set up virtualized datacenter infrastructure faster

VergeIO has launched an open source infrastructure-as-code (IaC) software tool, Terraform Provider, allowing customers to set up its virtual datacenter…

US colo LightEdge offers single tenant Nutanix cloud

US Nutanix users can get a single-tenant cloud just for their workloads from LightEdge, eliminating noisy neighbor resource-limiting problems. LightEdge…

Storage news ticker – August 14 2024

The Active Archive Alliance released a report, "How Active Archives Support Modern AI Strategies," saying its members' products could be…

Dell ups stakes in VMware battle with Nutanix-powered servers

Dell is stepping up its attack on Broadcom’s VMware customer base with a deal to run Nutanix software on its…

VergeIO claims fast VM migration from VMware

Virtualized datacenter supplier VergeIO reckons it can migrate hundreds of VMware virtual machines in seconds, providing a quicker and better…

Storage news ticker – August 2

Data protector Acronis has shared research from the first half of 2024 in its biannual cyberthreats report, “Acronis Cyberthreats Report…