Liqid composability tech aims to turn Dell servers into GPU powerhouses

Liqid can turn Dell servers into on-prem AI model training powerhouses by making up to 30 NVIDIA L40S GPUs available…

Storage ticker - 10 May 2024

Ceramic storage developer Cerabyte is now an official partner of CERN OpenLab together with a handful of selected corporations: Intel,…

GigaIO debuts mini supercomputer on wheels for the edge

GigaIO and SourceCode have announced the launch of Gryf, a carry-on suitcase-style supercomputer. This co-designed GPU server features composable GPUs,…

Storage news ticker – March 15

ETL connector biz Airbyte announces that there are more than 5,000 data connectors, created by users with the Airbyte no-code…

Storage news ticker – November 24

AvePoint has announced the launch of AvePoint Cloud Backup Express, which, running on Microsoft 365 Backup Storage, enables customers to…

Storage news ticker – November 20

Niraj Tolia Dr. Niraj Tolia, Alcion’s CEO and co-founder, was awarded the Distinguished Alumni Award by Carnegie Mellon’s Parallel Data…

Oxide on-prem cloud computer reinvents the server rack

Startup Oxide has delivered a rack-level system providing cloud-style computing on premises as its first commercial product. Oxide was founded…

Storage news ticker – October 25

Data intelligence supplier Alation has signed up three new partners: Monte Carlo, Sigma Computing, and ThoughtSpot, all of which provide…

Public cloud ephemeral storage can't be persistent – right?

Four block storage suppliers use public cloud ephemeral storage drive instances. So can they be persistent despite being ephemeral? Yes…

InterSystems taps Volumez to provide storage

Block storage provisioning startup Volumez is rapidly expanding its capabilities, adding Azure cloud support to the existing AWS cloud and…

CloudFabrix wants to put the 'AI' in AIOps

Startup CloudFabrix has launched its Macaw chatbot, designed to bring generative AI to AIOps and upskill admin staff. The ground…

Storage news ticker – May 26

Data protector ArcServe paid DCIG to review its UDP 9.0 backup product. The resulting study found that ArcServe UDP 9.0…

Volumez swells thanks to $20M A-round

SaaS-based storage orchestrator Volumez has raised $20 million. This A-round of funding was led by Koch Disruptive Technologies, with participation…

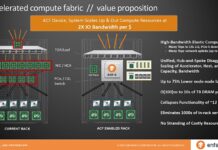

Enfabrica takes a shot at fixing AI compute scaling problem

Enfabrica is building massive scale interconnect silicon, a Server Fabric Adapter (SFA), an accelerated fabric silicon device to link intelligent…

VergeIO adds datacenter recipe book to VergeOS

Datacenter virtualizer Verge.io has delivered the Atria release of its VergeOS, adding Edge Edition software, edge site management, external backup…

Fungible shareholder sues company: Wants to inspect the books prior to $190m Microsoft deal

Fungible stockholder and ex-employee Naveen Gupta has filed a lawsuit against the company, seeking to "investigate potential wrongdoing and breaches…

Unifabrix CXL memory node boosts core use

Israeli startup Unifabrix demonstrated its Smart Memory Node at SC22 and we wrote an initial account of its technology here. The…

Storage news ticker – December 15

Apache Cassandra v4.1 is a milestone release that's mainly a feature update geared toward preparing for the major changes for…