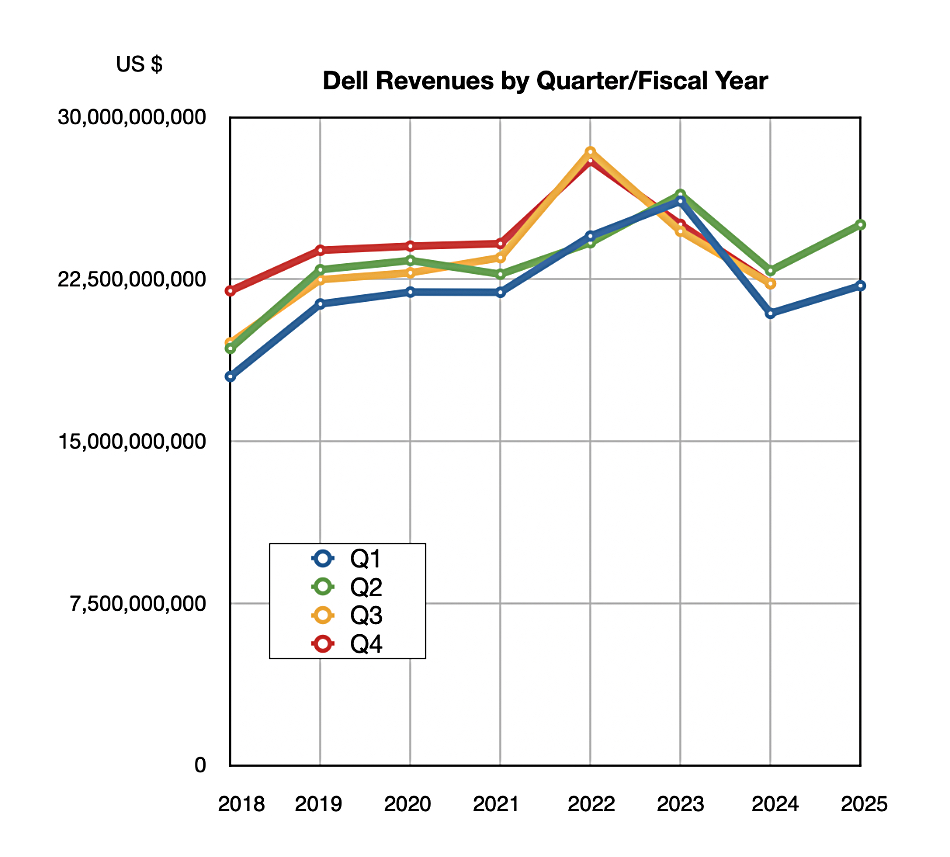

A massive rise in server sales led Dell’s second fiscal 2025 quarter revenues to a 9 percent year-on-year rise to $25 billion, with an $841 million profit, more than Nutanix’ entire $524.6 million quarterly revenue, but there was a slowdown in HCI sales.

Dell said there was: “Exceptional AI-optimized server demand and improved traditional server demand growth,” in the quarter ended August 2, 2024.

Vice-chairman and COO Jeff Clarke stated: “We executed well in Q2, and I’m really proud of our team and our performance.” The revenue number was “another record for our servers and networking business.”

Quarterly financial summary

- Gross margin: 21.2 percent vs 23.5 percent a year ago

- Operating cash flow: $1.3 billion

- Free cash flow: $1.28 billion vs $3.1 billion last year

- Cash, cash equivalents, and restricted cash: $6.0 billion vs $7.9 billion last year

- Diluted earnings per share: $1.17, up 86 percent y/y

The $1.7 billion downturn in cash and investments was the result of Dell making capital returns of $1 billion; repurchasing 5.5 million shares of stock at an average price of $130.03 plus paying a $0.45 per share dividend, and net debt paydown of $1 billion during the quarter.

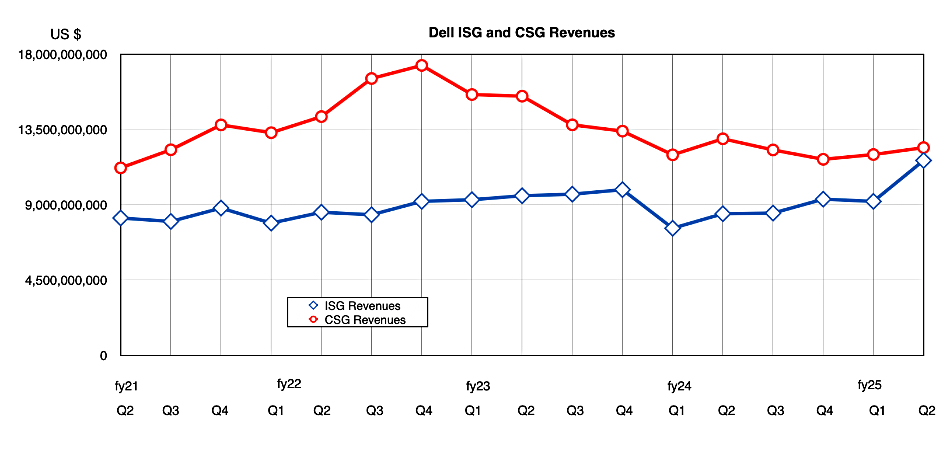

The two main Dell business units, the Infrastructure Solutions Group (ISG) and Client Solutions Group (CSG), had differing results with ISG (servers, storage and networking) revenues rising 38 percent Y/Y to a record $11.6 billion, while CSG (PCs, etc.) revenues went down 4 percent to $12.4 billion. In the CSG unit, commercial client revenue was flat at $10.6 billion, and consumer revenue was 22 percent down at $1.9 billion. ISG is now in a position to overtake CSG revenues after years of CSG being far ahead.

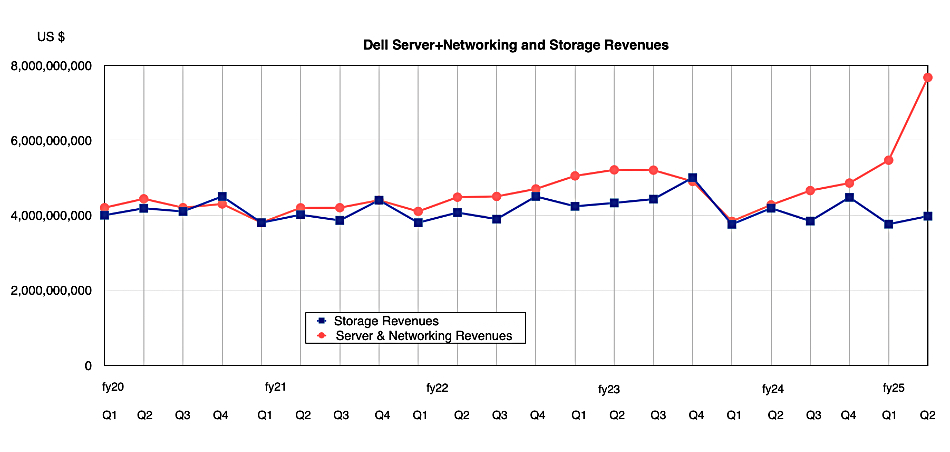

The ISG revenue driver was and is server sales, with a remarkable 80 percent rise in the combined server and networking revenue number to a record $7.7 billion. Storage revenue was $4.0 billion, down 5 percent.

Clarke’s prepared remarks expanded on this: “Our AI momentum accelerated in Q2, and we’ve seen an increase in the number of enterprise customers buying AI solutions each quarter. AI-optimized server demand was $3.2 billion, up 23% sequentially, and $5.8 billion year to date. Backlog was $3.8 billion, and our pipeline has grown to several multiples of our backlog.” This hints that next quarter’s server revenues should be impressive as well.

There was demand growth in storage, with Clarke saying in the earnings call: “Dell IP core storage demand, including PowerMax, PowerScale, PowerStore and PowerProtect/Data Domain grew double-digits in the quarter, a positive sign as we move into the second-half of the year.”

CFO Yvonne McGill said storage did well under the covers: ”We’re pleased with the sequential improvement in storage profitability. We gained scale with 6 percent sequential revenue growth. We were more disciplined in our pricing. We had a higher mix of Dell IP storage solutions and a better geographic mix with more North America activity.”

She also identified the storage weak point: ”This strong storage performance was offset by headwinds in the partner IP portion of our HCI (hyper-converged infrastructure) portfolio.”

Earnings call analyst Tony Sacconaghi suggested “that hyperconverged is either an enormous part of your business or was down by a huge amount.” Clarke confirmed that: “obviously, your conclusion is correct. The partner IP business was down quarter-over-quarter.”

Dell’s Investor Relations head Rob Williams added: “We haven’t broken it out specifically, but it [HCI] is obviously a large part of the business. And data protection would be the other area where there was a bit of decline year-over-year. So those two offset the increases in the other four businesses we mentioned.” The other four being PowerMax, PowerScale, PowerStore and PowerProtect/Data Domain.

Dell supplies VxRail HCI running vSphere and also PowerFlex HCI systems. There are well known VMware market issues following Broadcom’s acquisition of VMware. Dell signed an HCI partnership deal with Nutanix in the quarter, looking to grow its HCI business.

Back to AI

AI server sales dominated the quarter, with Clarke saying: ”Our unique capability to deliver leading-edge air and liquid cooled AI servers, networking and storage tuned and optimized for maximum performance at the node and rack level combined with leading ecosystem partners and world-class services and support continues to resonate with customers.”

There’s more to come: “Enterprise remains a significant opportunity for us as many are still in the early stages of AI adoption. We are also excited about the emerging sovereign AI opportunity, which plays to our strengths given our position with governments around the world.”

And: ”Most exciting, our AI server pipeline expanded across both Tier-2 CSPs and enterprise customers again in Q2, and now has grown to several multiples of our backlog. As we begin the second-half of the year, we have optimized our sales coverage to better focus on AI opportunities across CSPs, and both large and small customer segments and geographies.”

The outlook is excellent: “Our AI opportunity with Tier-2 CSPs, enterprise and emerging sovereign customers is immense. Our view is supported by an AI hardware and services TAM of $174 billion, up from $152 billion, growing at a 22 percent CAGR over the next few years. We are competing in all of the big AI deals and are winning significant deployments at scale.”

McGill said: ”We expect solid top line growth in the second-half of the year even as we continue to optimize our cost structure to enhance our competitiveness over the long-term.

“A big part of this optimization effort is leveraging AI to reimagine our business processes and drive higher productivity. To that end, in Q2, we took a $328 million charge for workforce reduction as we continue to position our business for the long-term.”

She added: “We’re using it [AI] to improve customer and team member experiences in sales, software development, services, content management and our supply chain. And in turn, we’re using our experiences to help our customers realize benefits of AI for themselves.”

It looks like fears about AI replacing human jobs are real.

Clarke said: “If you think about the use cases, the use cases are generally around large language models; small language models are coming. We’re already talking about technologies like agents and agent is a buzzword of our industry today, and we’ve just scratched the surface of how agents are going to help each individual’s productivity, help with specific skills, which provide an opportunity to take the millions of processes that are in businesses today and help automate them.”

Outlook

Although lagging currently, CSG has a positive outlook, according to Clarke, with: “modest commercial PC demand growth in the quarter …we continue to pursue profitable share focusing on commercial PCs, high-end consumer and gaming with our strong attach motion.

“We are optimistic about the coming PC refresh cycle, as the installed base continues to age, Windows 10 reaches end-of-life later next year and the significant advancements in AI-enabled architectures and applications continue.”

McGill said: “We expect [CSG] growth in the second-half of the year, particularly in the fourth quarter.”

The outlook of $24.5 billion +/- $500 million for the next quarter represents 10 percent Y/Y growth, with ISG revenues growing in the 30 percent region. The full fy2025 outlook has been revised upwards slightly, with revenues of $97 billion +/- $1.5 billion, again 10 percent higher than a year ago, with ISG up 30 percent or so and CSG flat. It looks highly likely that ISG revenues will overtake CSG revenues by the end of the fiscal year.