EDSFF – Enterprise and Data centre SSD Form Factor colloquially known as rulers. There is an SNIA EDSFF work group, the SFF Technology Affiliate Technical Work Group (SFF TA TWG), made up from 15 storage industry suppliers. The initial version of the specification was created by the SNIA SFF Technology Affiliate organization as a response to concerns about solid state data center storage and ways of optimising capacity, thermal properties and physicalmsize for different applications.

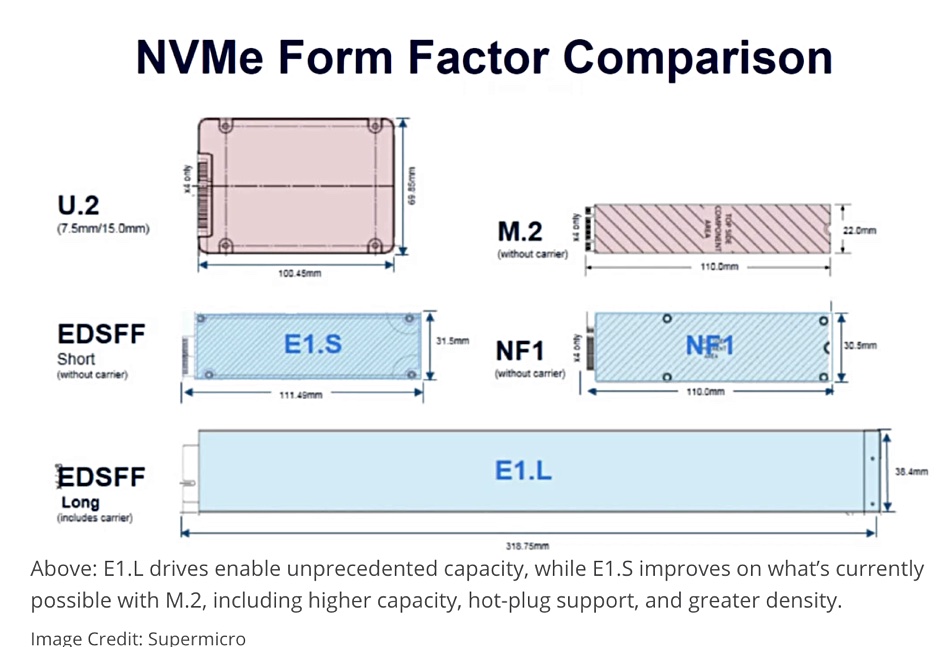

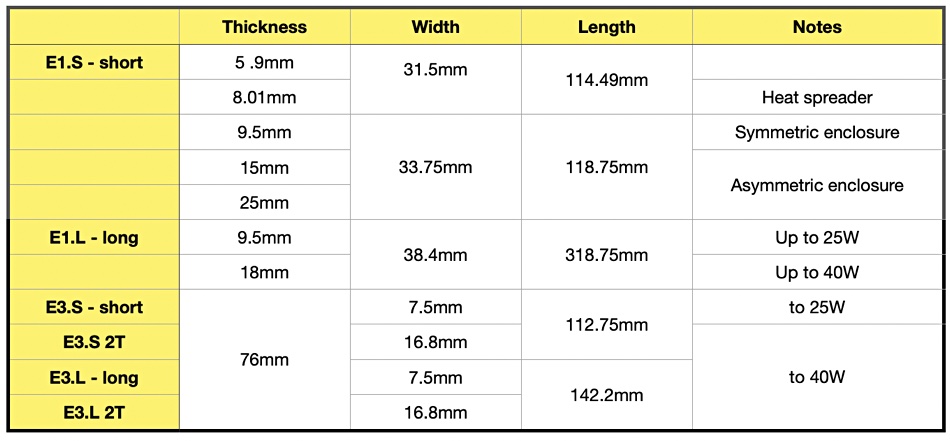

The idea is to move away from 2.5-inch and 3.5-inch disk-bay sizes for SSDs, which now come in these sizes as well as M.2 gumstick cards and PCIe add-in card (AIC) formats. There will be instead longer and thinner devices, the so-called rulers, which can provide up to 1PB of capacity in a 1U server, using 64-layer, TLC 3D NAND. Here is a table showing the EDSFF formats;

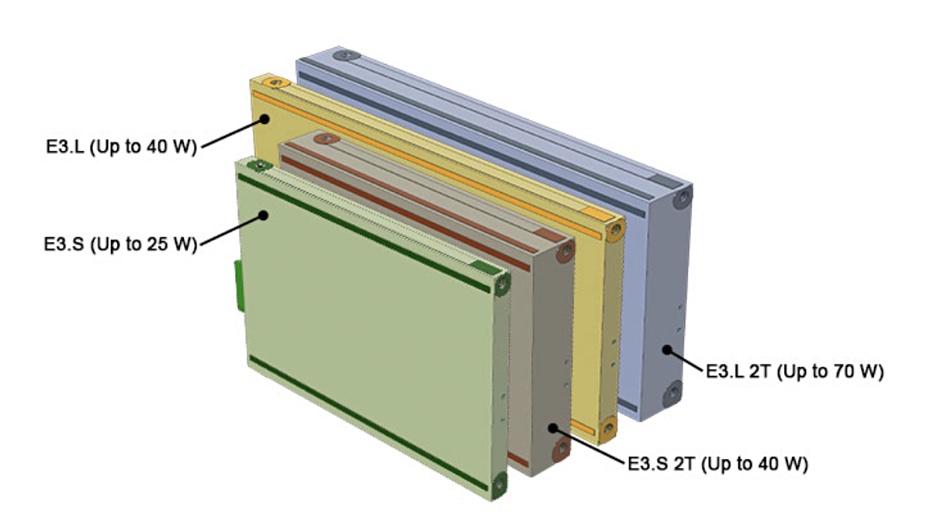

There are two basic formats, E1 and E3. Both come in short and long variations, with the E3.S and E3.L formats also having T variations. E3 SSDs support up to 16 PCIe lanes with power profiles of up to 70W. The E3.S form factor updates and replaces the U.2 2.5-inch drive format, inherited from 2.5-inch disk drive days.

The EDSFF is also working on a 3-inch form factor that is 76mm (3 inches) wide. This format has two thicknesses and two lengths: 7.5mm or 16.8mm thick and either 104.9mm or 142.2mm long. Download the format specs here.

A Supermicro diagram illustrates some of these form factors;