Mold flow analysis refers to the process of using software to simulate an injection molding production cycle. Using the physical characteristics of a specific manufacturing material, the software is able to predict how the mold will be filled during the injection process.

Mold flow analysis proves useful during the design phase as it allows engineers to test prototypes for potential issues like shrinkage, warpage, sink, shear stress, potential air traps, or improper fill patterns — prior to creating the actual mold to be used in the production process. It can also make predictions about how the mold will react when injected with pressurized molten material and during the cooling process, in addition to fiber orientation when using reinforced thermoplastics.

These predictions are useful for engineers, who can adjust molds as needed based on the simulation in order to create high quality, design-optimized parts. However, while mold flow analyses can be incredibly useful, the software can be expensive. Additionally, there are certain applications for which analysis may be unnecessary. Mold flow analysis is especially beneficial for parts with tight tolerances, complex geometries, and for projects with large enough scope that the costs of performing the analysis are justified.

This piece will delve deeper into the key economic and technical advantages that mold flow analysis provides engineers and product managers.

Technical advantages: Mold flow analysis and troubleshooting

One of the key advantages of mold flow analysis is that it can help engineers pinpoint specific design issues upstream, thereby optimizing part design early and reducing downstream costs associated with retooling.

Part designs with varying wall thicknesses can potentially cause problems, as the pressure of the injection molding process can cause unintended warpage and internal stresses. Flow analyses can detect and resolve these issues before a mold goes into production.

Further, it can help ensure that mold cavities are filled with consistency, mitigating the occurrence of air traps as well as surface defects like sink marks or weld lines. It may also help engineers determine the optimal location for gates — the area where the thermoplastic is injected into the mold cavity — reducing the need to re-tool molds for greater efficiency.

Additionally, mold flow analysis enables engineers to test the physical and chemical characteristics of different manufacturing materials prior to production, ensuring that the ideal material is used to align the part’s composition with its intended application.

Economic advantages: Mold flow analysis and ROI

Technological developments and advances in software engineering mean that mold flow simulations are able to provide greater accuracy in their predictions and analyses — which optimizes the design process and saves on overall production costs.

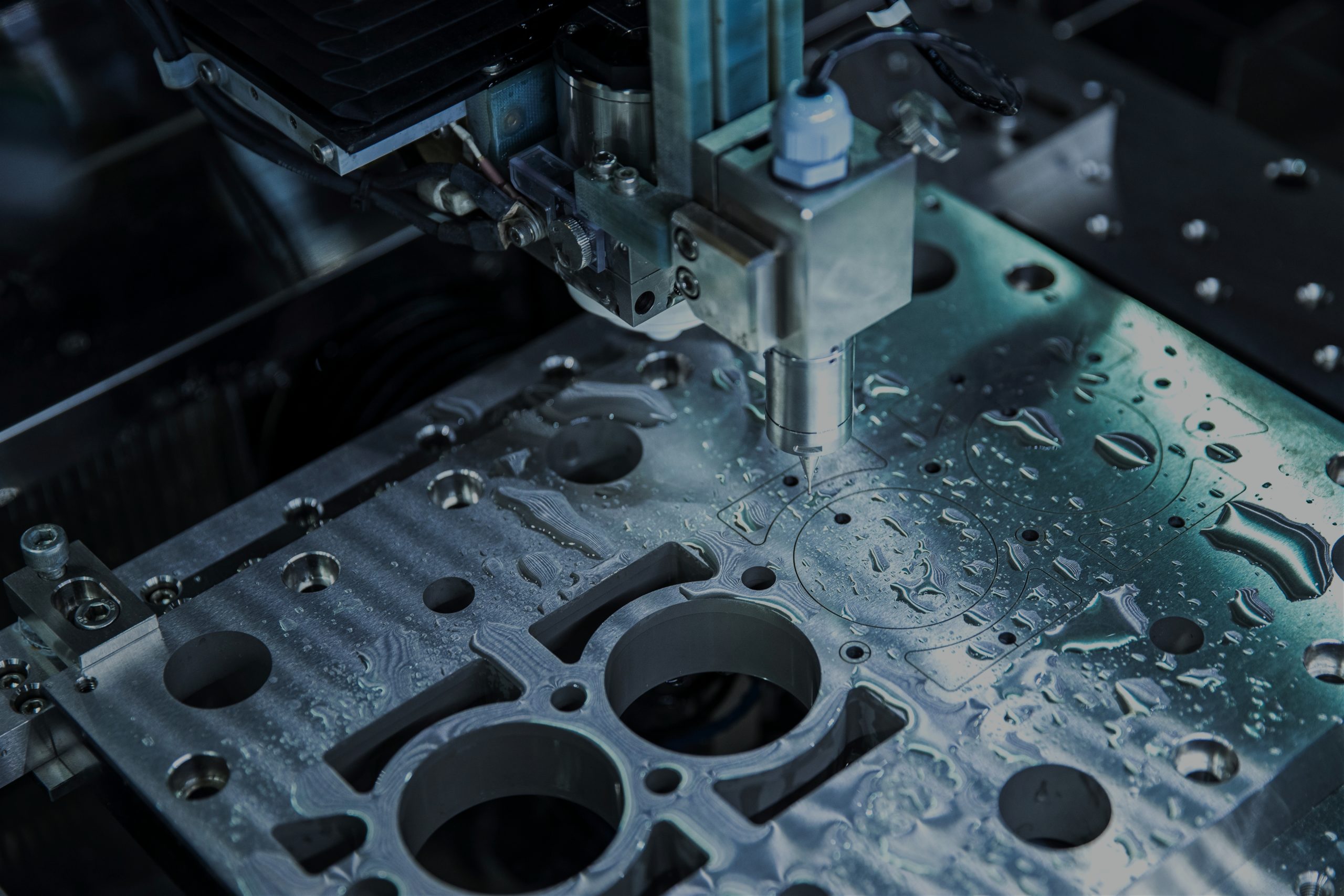

The injection molding process is frequently used for high-volume production runs because it allows manufacturers to quickly create highly accurate duplicates of the same part en masse. Molds have to withstand repeated exposure to highly pressurized molten thermoplastics, and therefore tend to be made of metal alloys or hardened steel.

Creating each of these molds is expensive and time consuming — they can easily require tens of thousands of dollars and weeks to tool properly — which is why it’s important for product managers to optimize part design before the mold is made. 3D printed prototypes can be updated in days, but recreating a metal mold can be quite costly and can take weeks.

Because injection molding requires such a significant upfront investment, it’s crucial that part designs be optimized for efficiency and cost-effectiveness in order to maximize ROI. While large production runs often recoup the costs of manufacturing by lowering the per-unit cost of each part, the economic impacts of poorly optimized product design becomes increasingly apparent as production volume increases.

As such, it’s crucial that engineers and product designers make part updates during the design phase. This helps guarantee that when the prototype goes into production, it yields high quality parts and remains durable over the course of the production lifecycle.

Optimize every part upstream with effective mold flow analysis

While incorporating mold flow analysis into the pre-production process is likely to increase the cost of manufacturing, this cost is generally offset by the resulting quality improvements. When properly used, the analyses and predictions offered by mold flow simulations can optimize the manufacturability of the part, improve the quality of its composition, and reduce time to market by streamlining the manufacturing process itself.

Fast Radius believes in pushing the boundaries of what’s possible. Our team is composed of engineers and designers who work hand-in-hand with customers during all stages of the production cycle to ensure that part designs are optimized for manufacturability and quality. If you’re ready to start an order — or if you’re looking for consultations for your next part application — don’t hesitate to contact us today.

Interested in learning more about additive and traditional manufacturing? Check out Fast Radius’s resource center to read about the different production services we offer, as well as the range of manufacturing materials available.