By Izzy de la Guardia, Application Engineer, Fast Radius

While the global pandemic has revealed many vulnerabilities in our supply chain, it has also bred innovation. In particular, 3D printing has enabled professionals and hobbyists alike to channel their fears into action with unprecedented speed and accessibility. We experienced this firsthand in the creation of our open-source respirator design.

Here is a glimpse into the process and how we were able to create four distinct prototypes and conduct three user-testing sessions in only two weeks by taking advantage of 3D printing, a cross-functional team, and our company’s personal and professional networks.

Rapid prototyping and user testing

As many Americans began to shelter in place mid-March, Fast Radius received multiple requests for 3D-printed respirators amidst growing concerns over PPE shortages. I was tapped by our General Manager, John Nanry, on a Friday afternoon to lead the design effort to respond to this need. Hours later, we had our first design ready to print, inspired by the open source designs of Copper 3D and La Factoría 3D

The main focus of our design was manufacturability on all of our in-house additive machines (Stratasys FDM, Carbon DLS™, and HP Multi Jet Fusion) by ensuring proper overhang angles and vacuum ventilation. We produced our first prototype on Carbon DLS that night.

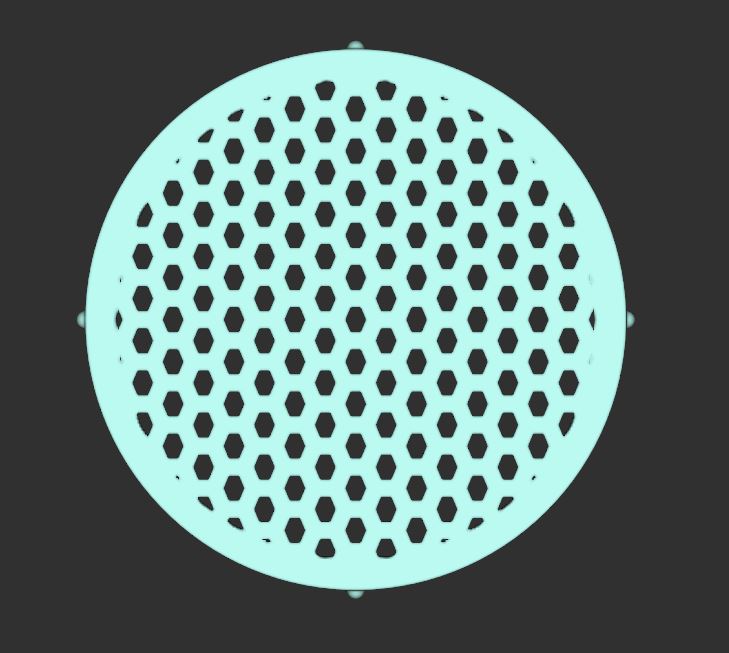

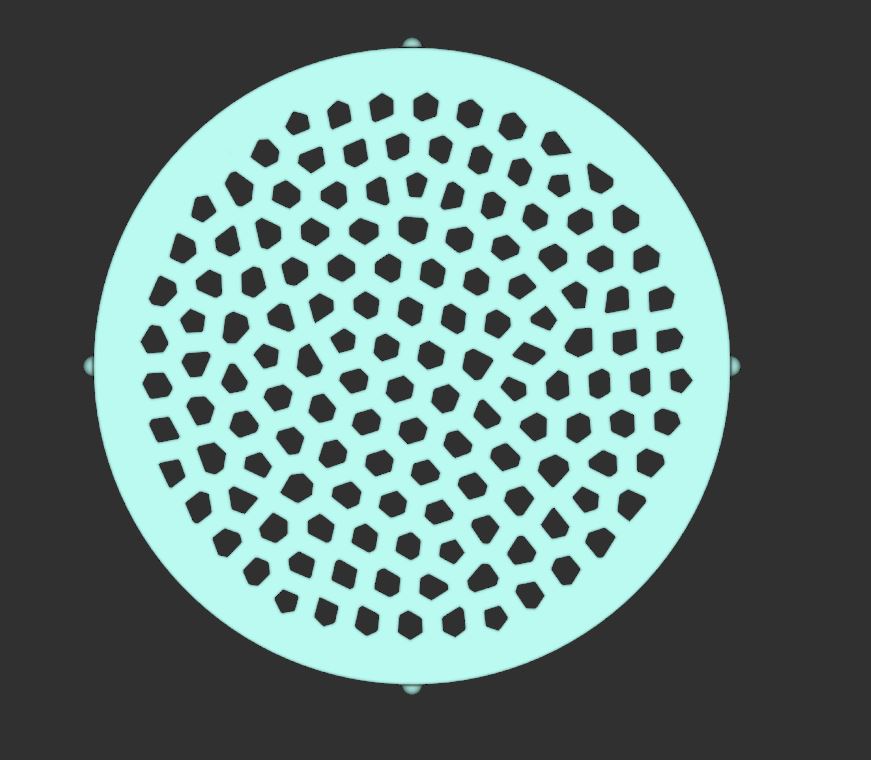

Advanced design tools like nTop Platform supported quick iteration, such as switching from a voronoi pattern to a more regular hex pattern that was easier for hobby FDM printers to handle

Our first printed prototype included FDM-friendly overhangs and channels to prevent vacuums on DLS

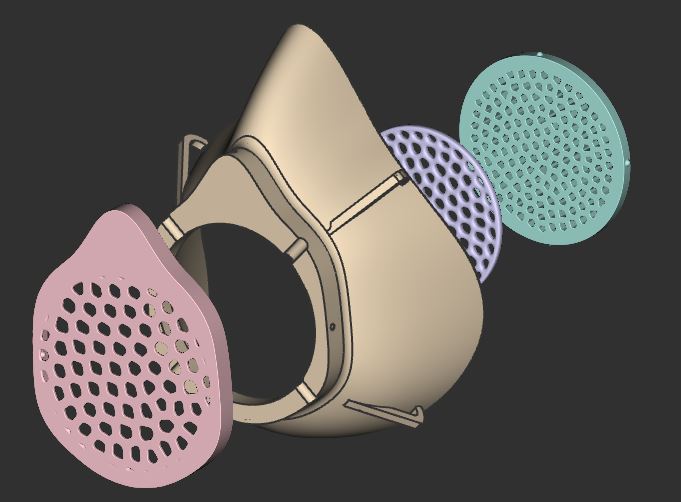

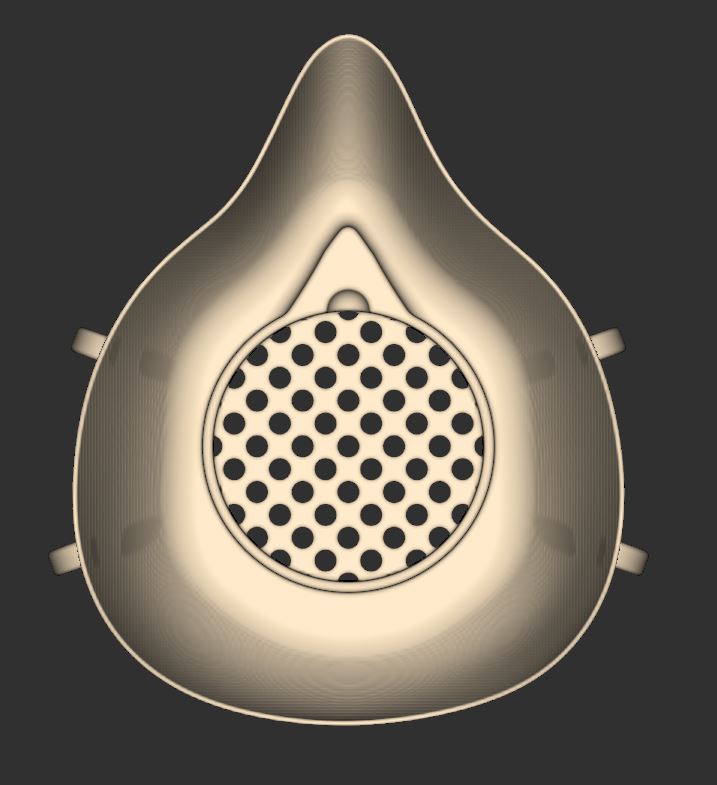

These prototypes informed further design changes: consolidating the front cover with the main mask body to print as one piece, thickening the strap loops for durability, and reducing the density of the grid pattern and making it circular for easier printing on FDM. We were able to start printing our second prototypes by Saturday night, only 24 hours into the project.

Our second printed prototype design consolidated parts (left). Inside of mask with recession to insert finger and pop out the snap-in filter cover (right).

In parallel with the design process, we tapped into our network to better understand the need and identify individuals for user-testing. In less than 24 hours, our friends at P33 connected us with a dozen doctors and employees at a medical research foundation to provide greater insight into N95 masks. Our employees also reached out to the medical professionals they knew. By Sunday, only two days after kicking off the project, we conducted fit testing with our second prototype on 10 individuals in four locations.

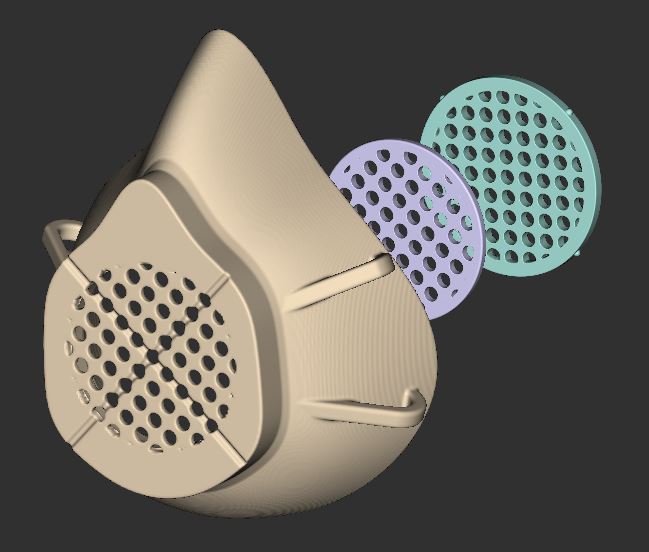

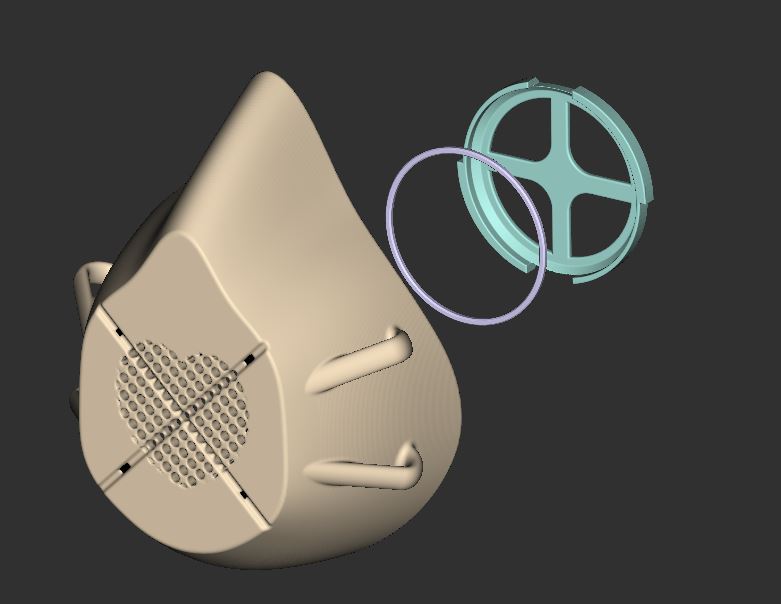

The next two weeks continued in this pattern — design, print, test, repeat. Our third printed prototype featured a redesign of the filter retention mechanism. The offset semi-circle perimeter geometry functions as a cam that locks the piece into place when twisted through friction (see below.) There are two tabs that force the cover down in the rotated or locked position to ensure a good seal around the filter. We created a version with a heart-shaped perforated area to make the mask less intimidating. Starting with this round of prototypes, we designed and tested masks in two different sizes.

Third printed prototype design with twist cap.

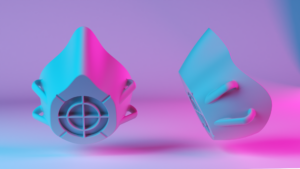

By the fourth prototype, we were primarily concerned with ease of breathing and proper fit. To address this, we tried to maximize the perforated region and minimize its density (sadly losing the heart) to reduce resistance to air flow. We also tweaked the measurements for the two sizes based on feedback from user testing. At this point, we were confident enough in the mask’s function and sizing to release version one as an open source design.

Design for accessibility

To make the mask available to as many people as possible, we created an open-source design that could be manufactured on household 3D printers. This decision added design and material constraints. A rigid mask couldn’t conform to a wide variety of face shapes, so we explored adding a flexible material to the inner rim of the mask to improve its seal to the face.

We prototyped a first concept using SIL 30 on Carbon DLS. We went on to test many methods for creating an effective seal to the face (described below), including a cut up glove, printed and molded silicone, moldable costume facial prosthetic material, FDM-printed TPU and PLA seals, and weather-stripping. Ultimately, we settled on weather-stripping, which is biocompatible, easily cleanable, and easy to source.

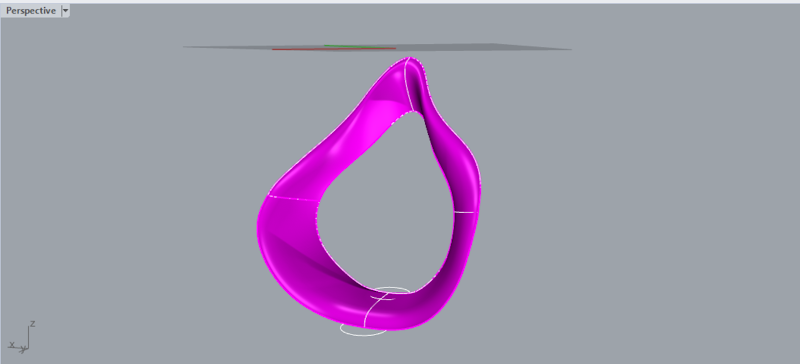

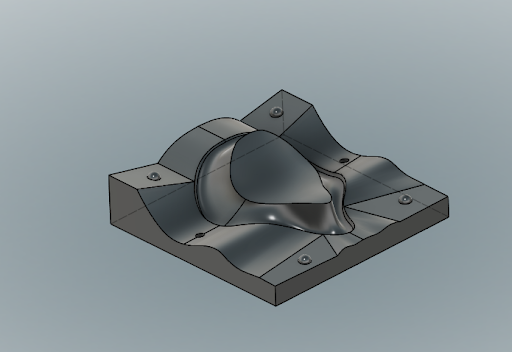

Form mockup for moldable silicone

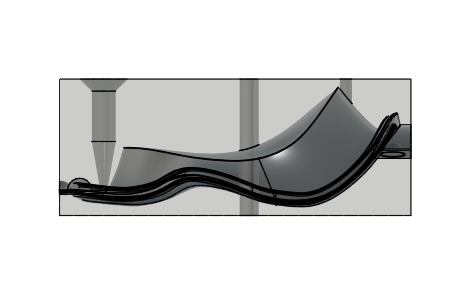

Integrated thin PLA seal

Rapid team formation

I attribute the successful rapid iteration on this project not only to the power of digital design tools and additive manufacturing technology, but also to the dedication and diversity of the team we pulled together from different parts of the company. Daniel Baker (Manager of Manufacturing Engineering) provided DFM feedback and pulled all-nighters to print and post-process prototypes. Tim Ouradnik (Application Engineer) sourced seal material, assembled prototypes, and drove all over Chicago to conduct socially-distanced user testing. Uriah Foley and Eldon Whitis (Lab Technicians) tested prototypes and explored integrated seals on their personal 3D printers at home after hours.

Nick Tonini (Program Manager) provided endlessly inventive solutions and design feedback. Jerry O’Leary (Chief Designer) improved on our designs and created concept renderings. Charlie Wood (Manager of Computational Engineering) provided leadership on seal design. Hallee Deutchman (Director of Materials and Manufacturing Technology) liaised with our partners and legal team before releasing the design. Sheila Seles (Senior Content Manager) and Austin Belisle (Content Specialist) packaged, published, and promoted our design.

The list of acknowledgements above is meant not only to give credit to the individuals that contributed to this process, but also to demonstrate the power of company culture in making new things possible. We worked on this project outside of our normal responsibilities and team structures because we wanted to create a product that could make an impact on the world beyond Fast Radius. This spirit crossed company borders, too; we are grateful for P33 and all of the doctors who contributed their time and expertise. If we learn nothing else from this pandemic, I hope that we continue to be intentional about breeding a culture of diversity, humility, and collaboration as we work to respond to pressing global challenges.

Our design is available and ready to print. You can find CAD files and instructions on our website.